In the world of industrial valves, Durco plug valves have been a mainstay for decades, providing reliable flow control solutions for various applications. Over the years, these valves have evolved and adapted to meet the ever-changing needs of modern industry. In this article, we will delve into the evolution of Durco plug valves and how they continue to play a vital role in the industrial sector.

The History of Durco Plug Valves

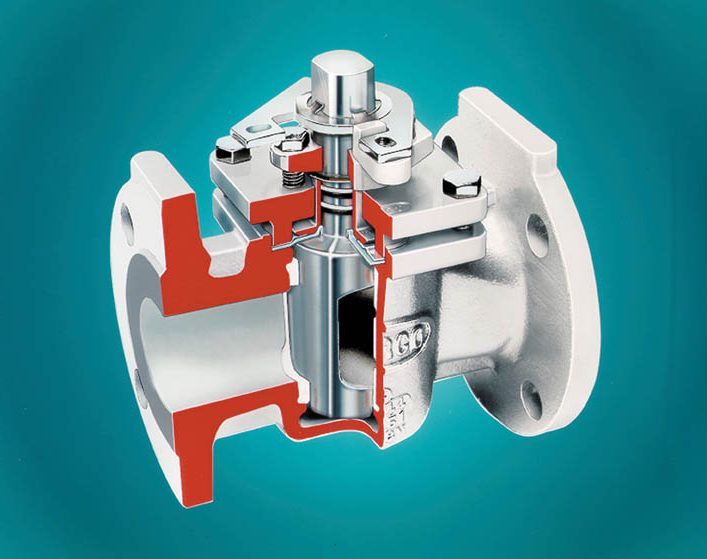

Durco plug valves have a rich history that dates back to the early 20th century. Originally designed for use in the chemical and petrochemical industries, these valves quickly gained a reputation for their durability, reliability, and versatility. The unique design of the plug valve, which features a cylindrical or conical plug that rotates to control the flow of fluid, made it well-suited for handling various types of media, including corrosive and abrasive substances.

Key Milestones in the Evolution of Durco Plug Valves

- Introduction of Corrosion-Resistant Materials: As industries began to handle more aggressive chemicals and fluids, Durco plug valves were made available in a range of corrosion-resistant materials such as stainless steel, alloy 20, and hastelloy. This allowed the valves to withstand harsh operating conditions and extend their service life.

- Development of Advanced Sealing Technologies: To improve the sealing performance and reduce the risk of leakage, Durco plug valves incorporated advanced sealing technologies such as graphite packing, PTFE seals, and metal-to-metal seals. These innovations enhanced the reliability of the valves in critical applications.

- Enhanced Design Features: Over time, Durco plug valves underwent design enhancements to improve their efficiency, ease of maintenance, and overall performance. Features like self-adjusting packing, blowout-proof stems, and bi-directional sealing further increased the appeal of these valves in industrial settings.

Applications of Durco Plug Valves in Modern Industry

Today, Durco plug valves are utilized in a wide range of industries and applications where reliable flow control is essential. Some of the key industries that benefit from the use of Durco plug valves include:

Oil and Gas

- Upstream drilling operations

- Refining and petrochemical plants

- Pipeline transportation

Chemical Processing

- Chemical manufacturing facilities

- Pharmaceutical production

- Water and wastewater treatment plants

Power Generation

- Steam and gas turbine systems

- Nuclear power plants

- Hydroelectric facilities

Water and Wastewater

- Municipal water treatment plants

- Industrial wastewater management

- Desalination plants

The Future of Durco Plug Valves

As industries continue to evolve and demand more efficient and reliable flow control solutions, the future of Durco plug valves looks promising. Manufacturers are constantly innovating and improving the design and capabilities of these valves to meet the changing needs of modern industry. Some of the key trends shaping the future of Durco plug valves include:

Integration of Smart Technologies

- Remote monitoring and control capabilities

- Predictive maintenance features

- Data analytics for performance optimization

Focus on Sustainability

- Development of eco-friendly materials

- Energy-efficient design solutions

- Reduced environmental impact

Customization and Adaptability

- Tailored solutions for specific applications

- Modular designs for easy integration

- Quick response to changing industry requirements

In conclusion, Durco plug valves have come a long way since their inception and continue to be a preferred choice for flow control in modern industry. With a strong focus on innovation, reliability, and adaptability, these valves are poised to meet the challenges of the future and play a vital role in shaping the industrial landscape.